Extension Cord Reel - Easy Build Plans

I am continuously trying to improve my basement shop. Whether it's with new tools:

-table saw

-miter saw

-homemade disc sander

Or whether it's with things i build to help organize:

-nail gun case

-organizer cart

The next thing that i've noticed to be a problem is a convenient extension cord. In the past every time i needed to plug something in i had to take down the orange extension cord from the peg board, unwind it, and plug it in. Then when i'm done with the tool i need to rewrap it and hang it on the board. It was a pain.

Last Christmas i got an extension cord that attaches to the ceiling in the garage. It's spring loaded and will automatically reel back up into its housing. I use it all the time in the garage.

The one in the garage cost around $40 and is quite big. I didn't really feel like buying one and if i hung that from the ceiling in the basement i would constantly be hitting my head on it. I wasn't 100% sure where i even wanted to mount it in the basement. The ceiling was convenient in the garage, but perhaps on the wall or under the workbench would be better for the basement.

So i started with some sketches on paper as usual.

I quickly realized that the complicated part of the reel is winding up a cord and not having the plugged in end become all twisted. I'm guessing that with the store bought extension cord reels there is some sort of fancy roller bearing mechanism that can rotate without becoming twisted.

Eventually i came up with a design that involved the plugged in end of the cord to come out the center of the reel. I still wasn't super comfortable with the design, but i thought it would work well enough.

I decided to make the 'wheels' out of OSB, a material that i have used a lot recently. I built the nail gun case and cart organizer out of that type of wood.

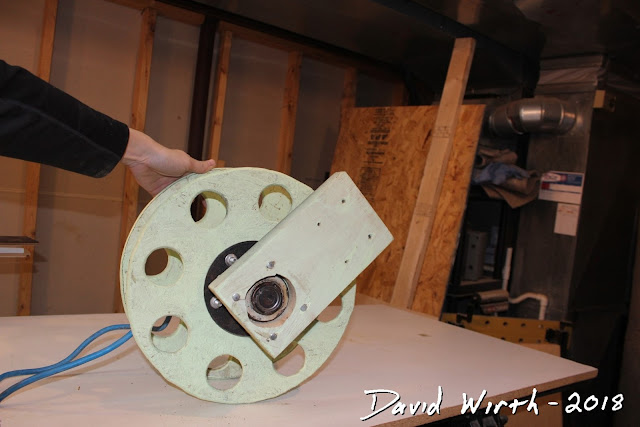

For the spinning/rotor part of the reel i used something i just had lying around, the old hub from my car. A week earlier i replaced one of the rear hubs off my Pontiac Grand Prix.

The old one wasn't broken, just the ABS sensor was cracked. It was a little overkill but i thought it would work. If it can hold up 1/4 of a 2000 lb car, it should be able to hold up a 4 lb extension cord.

For the center of the reel i wanted to use a short piece of PVC pipe. A 3" diameter pipe was perfect, and i was able to drill a large hole in it for the extension cord to pass through. The only difficult part was in how i was going to attach it to the wood.

But here's all the materials i needed set out. I also wanted to use a scrap piece of 2"x6" pine for the mount. Something that i could bolt to the hub and screw to whatever i was going to hang it off of.

I started by cutting out the 2 circular ends of the reel. Also i decided that cutting some holes in the ends would be functional for a couple of reasons. Mainly it would provide a type of handle for me to spin the reel. I couldn't really attach a handle, your arm would hit the end of the extension cord coming out of the center of the reel. But by adding holes it gave me something to grab onto.

Mount PVC to wood with mechanical rivets.

I rounded over the wheels and the cut-out holes with the router. Just a simple round-over bit to remove the sharp edges.

Next i measured, marked and drilled out the holes to attach the hub.

At this point i still wasn't sure how i was going to attach the PVC center piece to the wood ends. Ultimately i decided to make some small metal 90degree brackets and rivet them together. I'm still not happy with how that part turned out, but i still have no better way of connecting them.

In order for the hub to fit flush with the 2x6 i had to cut out a circular section. Then i drilled 4 holes to attach them together with bolts. With everything bolted together it seemed like it would work ok. Although the steel hub made it overly heavy.

When i plugged it into the ceiling power strip it seemed like it would work fine. But as i started winding the cord onto the reel i realized that there might be a problem. The cord really started to become twisted at the plugged in end. I would have to leave plenty of slack at that end and hope that the constant twisting and untwisting wouldn't damage the wire.

So i stood it back off the ceiling to do the finishing touches. I sanded everything down with the belt sander and palm sander. Then i put 2 coats of some old paint i had lying around and 2 coats of polyurethane.

It was kind of obvious that i didn't need to make the reels that large. I probably could wrap 200 feet of extension cord on the thing. But i only needed around 20 feet. If i had to make another one i would have made the reels a lot smaller.

Just another piece of the puzzle in making the shop easier to work in.

Video Transcript:

so something I made for my workshop a

bunch of years ago and never really

showed anybody how he made it is this is

an extension cord reel and the reason I

never really showed anybody how I did it

was because I never felt like it was

quite done it it works but it's not

perfect it's good for a small shop not

for a big one and I was looking for

something that I could just reel out

like in the garage I have a reel from

the top that I cranked up and cranked

down what's coming up with different

ideas of pipes and wheel bearings and

just last week I changed the rear hub on

the back wheel of my car and this is the

old one and it's spins pretty easily

it's really heavy really heavy duty I

have a quick sketch and I'm just gonna

make it out of oh s bead particle board

because that's what I have lying around

and we'll see how it goes well the first

step is determining how big to make the

circle and this is just scrap I have

lying around that's 16 inches so I'm

think I'm gonna make it 15 and a half

just so I have screw into that center hole and I can

leave that bit right in there so I'm

going to take a sharpie up and draw this

circle it'll hold it right in place and

this will be the 15 and a half inch

circle nose close that I'm going to use

all right there's a the layout lines that I did on the piece

that will attach to the hub this die

outer diameter is this here I'm gonna

cut that out and I just kind of

eyeballed right angles and drew this

pizza shape with the lines here

okay because I'm using such a large bit

it's binding up a little but that gave

me a hint on what I should be doing and

that's drilling halfway through with one

and because the bit sticks out a little

bit the holes are on the other side so I

can cut it from the backside and I won't

get any tear out as you can see from

these holes because I'm coming at it

from both directions that's all the way

through nice clean hole a bit and that's

that and obviously so I don't have to

remeasure redraw anything I'm just using

a sharpie and tracing all the holes that

I already drilled out it's the center

section cut out and I just need to drill

these holes and it will fit right over

that now real quick way that I transferred

the marks from here onto this board I

took a big sharpie and I marked up the

ends of these and I set it on there I

lined it with that center hole and it

took a hammer and when I hit it just

gave faint impressions on here that I

can mark for the holes to be drilled out

and I got five of them alright I just

got done cutting out the holes for the

hub bolts I used a half inch bit and I

had to do it on the drill because the

drill press doesn't have enough of a

reach I was going this will beat the

back and how it will mount to the wall

and then this piece would fit on the

front okay here's the piece of PVC I just cut

out it fits in the center of the hub I'm

gonna mount this here and before I do

that I have to drill a hole in the

center of this PVC so that a cord can go

through come out and come out the front

because that's where I'm going to

connect it it's not a great design I

would have liked to somehow fit the cord

out the back but with this hub there's nowhere to go

and it has to come out of the center

somewhere that way when you wind it up

the inner part doesn't get tangled only

the outer part winds up and just to

knock down some of these sharp edges I'm

using a roundover bit on the router

I had cut out the wheels before I'm the

inner piece with the hole in the middle

where the court is gonna feed through

and out the front but I wasn't sure how

I was gonna attach the wood wheels to

the PVC Center axle and I thought about

it and I came up with just making a

whole bunch of small little right angles

out of steel and then riveting them to

the wood and to the PVC I was thinking

about making out rings and screwing it

together and bolting it together this

just seemed like the the most stable

secure way and then on the back I bolted

the back of the wheel axle to 2x6 which

I will attach to the wall

once again I'm going to feed the

extension cord through the center aisle

at the front that's where it's gonna

plug in and I'll still be able to wind

it up I ended up hanging it from the

ceiling I'm just test fitting it right now I

just have a couple bolts I'm gonna take

it down and sand it and everything but

one bit of a design flaw that I saw was

that this Court is gonna get all twisted

up because it is even though it's

passing through it's gonna be spinning

so I don't know how I'm gonna fix it you

can see it's getting all twisted up here

now it is working for you know I'm never

gonna need to take out more than 2

or so but I'm gonna have to think about

that so I'm happy with where it is on

the ceiling it's high enough up I'm not

gonna hit it but I'm gonna have to worry

about this cord twisting out so far it's

working pretty well I built it because

the cheapest extension cord reel you can

get is probably around 5

one at Harbor Freight the 2

footer it's like 5 isn't cheap but then again

extension cords aren't that cheap

hopefully you can get an old extension

cord and use that the heart of this unit

is an old car hub a wheel bearing right

here out of an old car I changed it on

my Grand Prix and I used this wheel

bearing you don't need something this

heavy duty but this is definitely robust

enough to hold up 2 top of that this this is the mount that

I mount to the joists and the reel

itself is just OSB particle board and a

piece of PVC pipe in the center now the

real reason when I say it's not quite

done it's not quite perfect I'm an

extension cord really you have the one

part of the cord that doesn't move and

the other part that unwinds and

somewhere in that unit there's a 36

swivel that allows electricity flow

through but it doesn't tangle the court

and that's the part I could never really

get over and figure out so when I unroll

this and it unrolls like this part of

this court kind of tank

goes up which is why this is only really

good for about 2 have a 25 foot cord on here and that's

all I really want to use because

otherwise it's just going to tangle up

you'll see when I mounted on the ceiling

but at the center of this this is where

the cord comes out of the middle I

actually have a hole cut in this PVC

pipe which is where this wire feeds

through and you can see as I unwind it

it's actually twisting this cord in the

middle that's it over so to mount the

PVC to the particle board I just used

some metal tabs and I riveted them in

and that's how it's fine and to transfer

the court from the reel off the reel I

drilled a hole in this PVC and it comes

out here so it's still tangling up but

hopefully in just one direction and it

has I'm sure it's maybe shorten the life

of the court but there's no real damage

to it it's just twist it up a little so

let's mount it to joists I'm gonna have

you want to find a spot obviously in the

shop that's in the middle that you can

reach it I use this for the table saw

it's a nice thick extension cord

probably like 12 gauge so it's enough to

handle a big tool I'm gonna mount it to

a joist and then I'll show you how it

winds up and it works so to mount it I

took this bracket off just four bolts

holding it on and I'm just using four

screws now I can lift this up into place

so here it is all mounted in place ready

to go you can see the mount on the

joists I bolted it down here and it's

all wound up and to uh to use it you

just pull the pull the cord down it

unrolls and then to wind it up you just

grab one of the handles and roll it up

now you might be thinking where am I

gonna plug it in well that's where that

lightbulb and all of this comes into

play I'm actually going to install an

outlet box where that light is and move that

down somewhere over here so I'm gonna

have to drill through a bunch of these

joists run a wire put in an outlet box

so I'm going to do that next

well it was just a couple seconds for

you but it took me an hour

a little bit more to replace that light

with an outlet box and move the light

down there but it's all hooked up now

this is connected you can see this is

the extension cord that comes out of the

middle and when I pull it this gets all

twisted up so when I pull the extension

cord down this gets all twisted up and

we have to have a spot for this to be

loose and become twisted so you can have

a hook or something it's always ready to

go it's always plugged in it's out of

the way when you don't need it I use it

all the time I use it for my table saw

which is in the middle of the room any

jig side just pull it down use it wind

it back up it's definitely great to have

in a shop like this and it works great

for a small shop we only need 5 1

at a time you don't need 5

of your garage door or something so if

you have an old car hub or if you have a

junkyard nearby you can use that if not

you can use any small wheel bearing this

isn't much weight but the hub is

definitely I mean I think I could hang

from this thing and it wouldn't go

anywhere that's how solid the hub is so

let me know what you think hopefully you

like it let me know if you have an idea

for how to get that swivel so I don't

get that cord twisting up like this there's got to be

some sort of swivel out there that will

allow that I've never found it though so

let me know what you think

No comments:

Post a Comment