Fix Wobble on Disc Sander

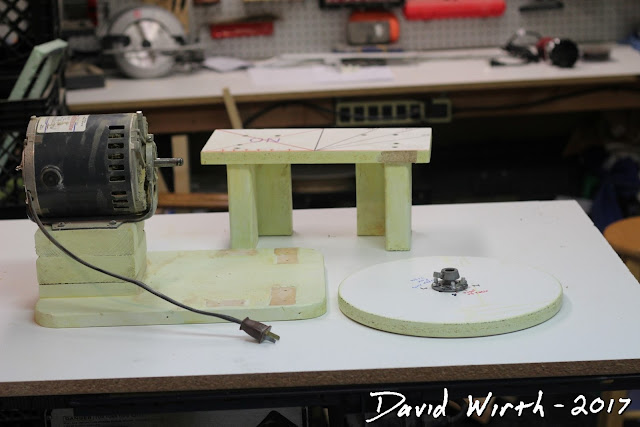

Back in 2014 i build a 12" disc sander using an old furnace blower motor. I used melamine for the 12" disc and built the frame out of 2x4's. It wasn't perfect but it's worked fine for years. The biggest issue was that the disc wasn't perfectly balanced and it wobbled.

And here's the original video from when i built the sander.

The problem occurred when i made the steel mounting flange between the motor and the disc. I welded a large washer to a steel pulley. Somehow during the welding it shifted and wasn't perfectly 90 degrees. So when i say it wasn't balanced what i really mean is that it wasn't perpendicular to the motor and that caused the wobble.

It looked ok, but not balanced and at 90 degrees.

Parts to attach flange to disc.

Lots of people complained that it was dangerous...they were probably right. They said that the unbalance would wear out the bearing and cause the disc to break apart.

So 3 years later i decided to try and fix it.

I started by spinning the disc by hand and marking the parts of the flange that high and low (1,2,3,4). Then i loosened the 4 bolts that held the disc in place and shimmed the low area with some paper shims.

I then shimmed it on the 2-3 side, with trial and error, until the wobble was virtually gone.

It took a lot of trial and error to finally get it right, i ended up having to put several shims at different angles to get the balance correct. But i finally got it so that it was almost perfectly perpendicular to the motor and the table.

Had i known it would have only taken a few minutes i would have done this years ago.

The next thing that needs to be done is to add a guard/shroud over the disc. That would block any debris that may get clogged and shoot up into the air. Or if the disc breaks apart it would keep it from flying in every direction.

Definitely safer now than it was before.

Fix Disc Sander Wobble

https://youtu.be/PDb5_I42sdkAnd here's the original video from when i built the sander.

Disc Sander - Make DIY Build

http://youtu.be/v0whmYkAV7UIt looked ok, but not balanced and at 90 degrees.

Parts to attach flange to disc.

So 3 years later i decided to try and fix it.

I started by spinning the disc by hand and marking the parts of the flange that high and low (1,2,3,4). Then i loosened the 4 bolts that held the disc in place and shimmed the low area with some paper shims.

I then shimmed it on the 2-3 side, with trial and error, until the wobble was virtually gone.

It took a lot of trial and error to finally get it right, i ended up having to put several shims at different angles to get the balance correct. But i finally got it so that it was almost perfectly perpendicular to the motor and the table.

Had i known it would have only taken a few minutes i would have done this years ago.

The next thing that needs to be done is to add a guard/shroud over the disc. That would block any debris that may get clogged and shoot up into the air. Or if the disc breaks apart it would keep it from flying in every direction.

Definitely safer now than it was before.

No comments:

Post a Comment